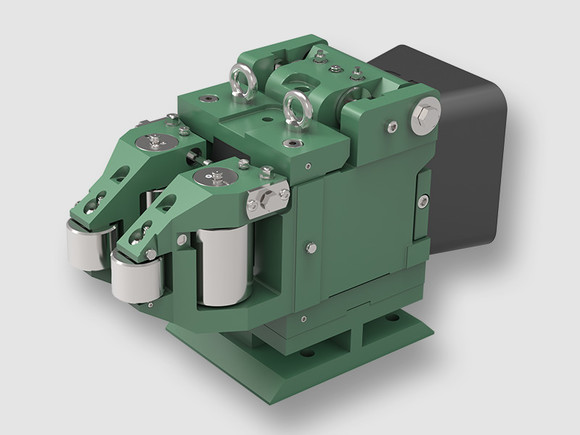

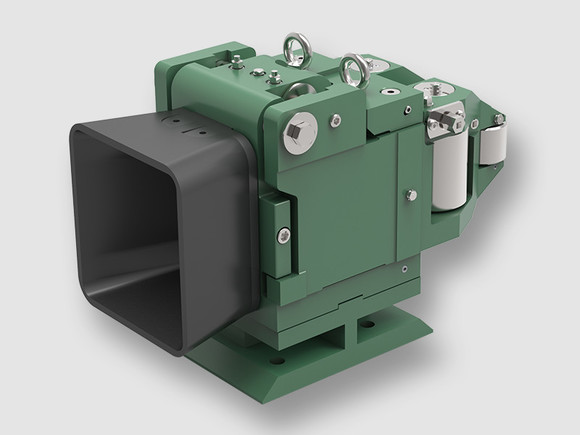

RE-FV

Description

Designed for the accurate entering of flat bars or near-flat barsinto a vertical mill stand for 'edging' with grooved or groove-less mill rolls.

The Guide is side mounted and provides a 'Roller Table' to support the product into the receiving passes. The smaller front roller ensures that the bar is supported continuously into the receiving pass. This continuous support ensures accurate guidance and preserves the surface integrity of the product, preventing surface defects.

A “Single Point” guide roller adjustment system ensures that the guide remains on pass centreline during any necessary adjustment. The leaves, or roller holders, move simultaneously and symmetrically about the guide and pass centreline. The Rear roller is provided with an eccentric adjustment.

These adjustable feature provide a parallel and level platform to support the guided bar.

Guide Features

- Guide versions incorporate incremental adjustment to the rear roller gap setting.

- Single Point simultaneous roll gap adjustment is provided on all versions.

- The multiple roller surface provides a surface defect free alternative to frictional or static guide systems.

- Special models with simultaneous rear guide roller adjustment are offered at extra cost.

- Nitrided and ground alloy steel bearing pins and wear parts provide a long working life.

- High capacity taper roller bearings are protected from the ingress of contaminants by lubricant and mill scale seals.

- Rugged, corrosion resistant cast steel or ductile iron construction.

- These guides provide accurate control over a wide range of flat and near-flat bar products.